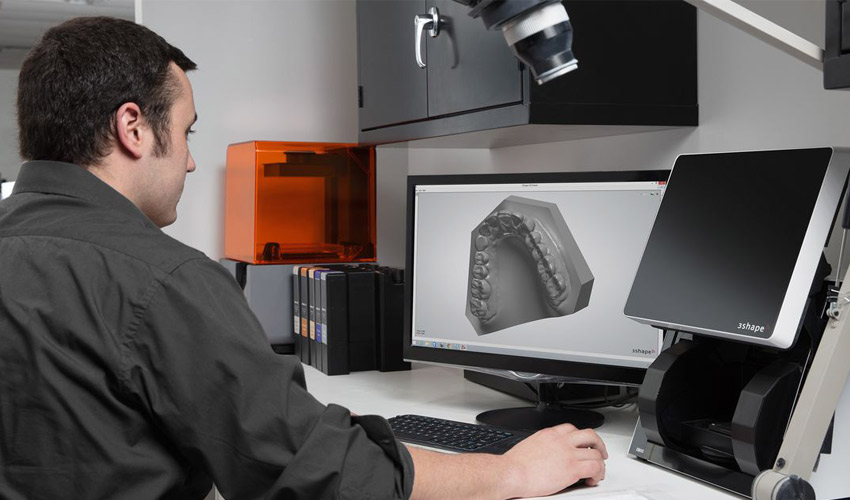

3D printing is an emerging technology, especially in the dental laboratory. This is due to new software, 3D scanners, and additive technologies, as well as post-processing techniques that increase efficiency and cost savings. Patients and doctors can benefit from the lower price and better quality of 3d printing dental labs. These are five ways that 3D printing has transformed the dental industry.

Improved Dental Product Quality

Dental printing with 3D printers is time- and cost savings abound

3D printing offers a host of benefits when it comes to the manufacturing of dentures. The greatest advantage is the increased quality. The quality of finished products was largely dependent on the skill of the technician. It is extremely difficult to create high-quality, consistent dental products that are free from errors. 3D printing has made it possible to create delicate structures. The component is constructed layer-by-layer using a software program. This is an improvement on a plaster model. A 3D model’s edges and lines are sharp, so the dentist doesn’t have to worry about them getting worn down. A 3D-printed model is more complicated than a milled one and has higher levels of detail.

Digital technologies make workflows easier, lower the chance of error, and require less labor. This results in both time and cost savings for the lab and the practice.

Dental Services Are Faster And More Accurate

Digital dentistry reduces the chance of error and automates labor. This results in labs and practices around the globe being able to save time and money. Manual model-making can be time-consuming and 3D printing allows multiple appliances to print at once. The digital copy is delivered electronically in just minutes. Once the scan is received, the technician can begin work immediately. It also provides a safe environment for technicians to work in, as they don’t have to deal with plaster and dust.

3D printers can also improve accuracy by converting digital images into physical objects. They print 16-micron thick layers one on the other. Both dentists and patients benefit from increased production and better end results.

Better Patient Experience

Clients are an important aspect of any industry, including the dental industry. Dental 3D printers can create models of patients’ problem areas to prepare them for surgery. This helps reduce anxiety and increases patient acceptance. Digital elements make it easier to do things faster, making patient visits much more pleasant.

Helps To Save Money

A 3D printer can help patients and dentists save money. The cost of operating a dental lab can easily reach $100,000 annually. This compares to the $20,000 one-time price for a top-model 3D printing machine, which includes a supply of materials. While the lifetime cost includes ongoing materials, it is far less than running a dental laboratory. Additionally, the ongoing cost of employing skilled personnel to make dental implants is significant. Depending on how much work is required, it could cost as much as $20,000 per year. Dental professionals aren’t the only ones who can save time and money with dental 3D printers. Dental 3D printers are able to reduce the cost of materials and labor, which means lower prices for patients. Patients also have fewer return visits because of the improved accuracy and speed.

Depending on the treatment required, it is possible for the total cost of dental care to drop by up to 80 percent. The accuracy of the work is also much better, which means happier patients.

Housework

The work of dental laboratories can be done in-house by dentists. These printers are very user-friendly. This means that you don’t have to pay for lab labor. The printers can be operated by dentists who are able to produce models, crowns, bridges, and other items that could otherwise only be made by technicians. They are often overlooked by dental offices, and they end up spending over $100,000 annually on lab work due to labor and material costs. For dentists who outsource lab work, long wait times and shipping costs add up to huge amounts of money.

This is not good news for patients or dentists. It was also expensive. 3D printers can be used to print dental work. Most industrial 3D printers are expensive at between $20,000 and $100,000+, but dental professionals can get desktop 3D printers at a fraction of the cost. This allows them to print faster and has a higher-quality image. If used correctly, the medical industry believes this technology could lead to a revolution in medicine. It allows for groundbreaking innovations that could lead to medical science scaling exponentially. These are only a few examples of the wide-ranging changes digital dentistry and 3D printing are bringing to the dental industry. It’s clear that digital dentistry is the future of the dental industry. There are many exciting opportunities for patients, dentists, and technicians.

You may also like

-

The Role of Technology and Innovation in China’s Economic Expansion – Kavan Choksi

-

Can Data Science help control food wastage in Mumbai

-

The Collaborative Power of WebLOAD and ChatGPT in the New Explainer Feature

-

NaaS Technology Plans to Acquire Charge Amps for US$66.4M to Collaborate on EV Charging Innovations and Energy Sustainability

-

Building Collaborative Applications with Mendix Team Server